EZ Clean family of filtration systems

The ZGF EZ Clean filtration systems (Phoenix and EZ Series) are the most advanced, best in class, automatic, non-disposable liquid filtration systems in existence.All EZ Clean filtration systems utilize the ZGF Spring Filter element. The ZGF Spring Filter element sets the standard for permanent media, fully automatic, self-cleaning filters. The absolute gap allows ZGF filter systems to efficiently and effectively capture contaminants from liquids; and the unique continuous coil design allows for complete cleaning of the filter element with each backwash.

The EZ Clean family of filtration systems includes the following models:

| EZ Clean automatic, non-disposable media, liquid filtration systems | ||||||

|

Product |

Flowrate (GPM) |

Material of Construction |

ASME Section VIII |

ZGF Control System |

Operating Pressure |

Operating |

|

40 – 250 |

|

No |

|

45 – 120 |

Pneumatic 190°F |

|

|

Electro-Pneumatic 160°F |

||||||

|

> 250 |

|

No |

|

45 – 150 |

190°F |

|

|

> 200 |

|

Yes |

|

45 – 192 |

190°F |

|

|

> 200 |

|

No |

|

45 – 120 |

190°F |

|

|

1 – 50 |

|

Yes |

|

45 – 192 |

190°F |

|

|

NOTES: 1. The solids loading, physical characteristics, material and density of the particles impact system sizing and design flowrate. |

||||||

Liquid Filtration Systems from Zero Gravity Filters

Our wide variety of EZ Clean filtration systems are detailed below.

Phoenix Automatic Liquid Filtration SystemThe EZ Clean Phoenix Automatic Liquid Filtration System is the most advanced, automatic, non-disposable liquid filtration system. The compact (18 in3), economical design utilizes six (6) Spring Filter elements arranged in a radial configuration around the inlet chamber and is designed to handle flow rates from 40 gpm to 250 gpm. The Phoenix's patented and simple design allows for 24/7 uninterrupted operation, eliminating downtime.

|

EZ100 Automatic Liquid Filtration SystemEach EZ Clean EZ100 pod houses a single Spring Filter element and is used in many different applications. It is suitable for low flow (1 - 50 gpm) . The modular pod design allows for multiple pods to be configured in parallel when flow requirements are greater. The EZ100 liquid filtration system is available in either our standard industrial version or an ASME Section VIII version that is uniquely suited for refineries, chemical plants, Oil & Gas fields, or other applications requiring pressure vessel registration.

|

EZ900 Automatic Liquid Filtration SystemThe EZ Clean EZ900 is our newest and most efficient liquid filtration system utilizing the ZGF Spring Filter element. The EZ900 pod is fabricated from the same building block as the Maggie MG2600. The EZ900’s modular “pod” design houses nine (9) Spring Filter elements and is capable of meeting any flow requirement greater than 250 gpm. The EZ900’s stainless steel construction allows for use in a wide variety of applications and industries.

|

Tornado Centrifugal SeparatorThe EZ Clean Tornado is a patented centrifugal separator that puts a new spin on an established technology! If you are looking for economical particle removal, the Tornado separator is your new choice for centrifugal separators. Having no moving parts or media, it is a simple but extremely innovative device that effectively removes particles without any regular maintenance. With sizes ranging from 2” to 8”, individual Tornado units can handle flows from 52 gpm to 1,500 gpm. Tornado centrifugal separators are used in Power Generating plants, Automotive plants, Steel Mills, and even in the Oil & Gas fields. They are utilized to filter machining coolant, wash solutions, cooling/process water, quench fluid and many other process fluids.

|

EZ700 Automatic Liquid Filtration SystemThe EZ Clean EZ700 liquid filtration system was designed to meet the needs and requirements of the oil & gas industry, and now can be used in any application requiring pressure vessel certification. The modular “pod” design houses seven (7) Spring Filter elements, can meet any flow requirement greater than 200 gpm and allows for 24/7 uninterrupted operation. The EZ700 is manufactured to ASME Section VIII standards and meets all the stringent design and manufacturing requirements for equipment utilized in the oil & gas industry.

|

EZ MAG Automatic Liquid Filtration SystemSome processes require both magnetic separation and a barrier filter. Your process stream may contain both magnetic and non-magnetic material, such as steel and aluminum. Why purchase two separate systems? The EZ MAG combines the capabilities of the Maggie and EZ900 into a single system with one set of valves, one set of controls, and the footprint of a single system. This reduces system complexity and floor space requirements while saving money. The EZ MAG is the ideal solution in steel mills, tube mills and paint pre-treatment systems because it is the only permanent media, in-line filter that combines magnetic and barrier filtration in a single system. Contact us to learn more about the EZ MAG.

|

Automatic Liquid Filtration SystemThe EZ Clean EZ700S utilizes the ZGF Spring Filter element. The modular “pod” design houses seven (7) Spring Filters, can meet any flow requirement greater than 200 gpm and allows for 24/7 uninterrupted operation. EZ700S’s stainless steel construction makes it suitable for use in a wide variety of applications and industries.

|

Complete Filtration SystemsZGF can design and deliver a complete system to meet your objectives. We can provide our patented magnetic separation and/or filtration equipment with all other system components such as tanks, pumps, meters, controls, valves, etc. From design to start-up, ZGF can be your filtration system partner.

|

ZGF Spring Filter Element Self-Cleaning Filter

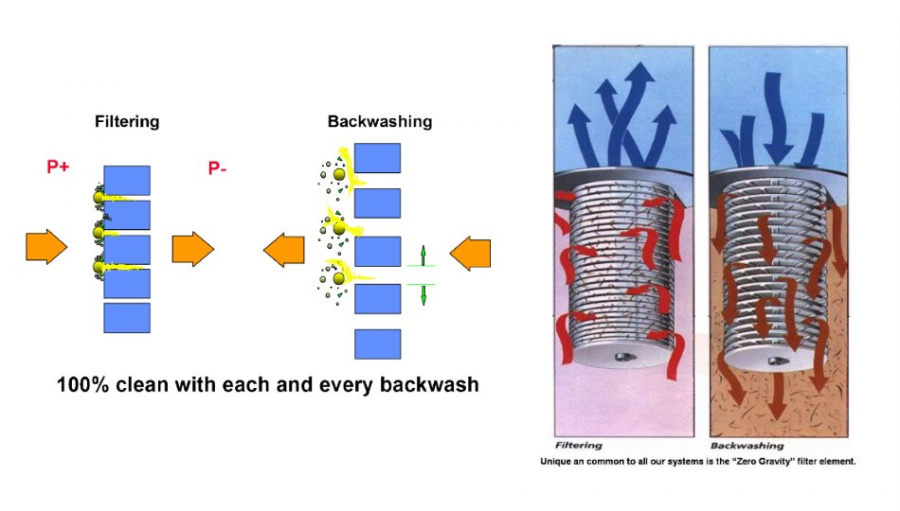

The ZGF Spring Filter is a 316 stainless-steel coil wound with a variable pitch that allows the filter element to open evenly from top to bottom ensuring that all contaminants are completely removed from the filter element with each backwash.

How the Spring Filter Element Works

The Spring Filter is manufactured with precision raised nidges. These nidges create an absolute gap that allow the Spring Filter to capture > 99% of spherical particles larger than the micron rating of the filter.

A normal coil does not open evenly from top to bottom causing inefficient cleaning. The full opening of the Spring Filter allows lodged or wedged particles to be easily removed as the gap is increased. While in backwash, the fluid flowing in the reverse direction causes the coil to shimmer which further enhances the cleaning capability of the backwash process. Click on the Spring Filter animation to see the basic principle of operation or to see the Spring Filter in action, click on the Spring Filter video.

The backwash is:

- Quick: 2 to 4 seconds per Spring Filter

- Efficient: <0.75% of total feed volume for backwash

- Effective: 100% cleaning of the Spring Filter with each backwash

Spring Filter Element Advantages

The ability of the Spring Filter to open uniformly along its entire length during backwash provides three distinct benefits not achievable by automatic backflushing filters with fixed geometric screens (i.e. wedge wire, etc.).

The benefits are as follows:

- Particles wedged or lodged are quickly released and washed away as the gap is increased / opened.

- Fluid flowing in the reverse direction causes the coils of the filter element to “shimmer” which further enhances the cleaning process.

- Fixed gapped filters (i.e. wedge wire, mesh, screens, etc.) do not provide enough backwash fluid to flow through a dirty filter element, particularly at micron ratings less than 100. The ZGF Spring Filter gaps open, allowing the necessary fluid to flow in a reverse direction for effective filter element cleaning. With the Spring Filter, there are no high-pressure nozzles, scrapers, or motors required for cleaning.

ZGF Spring Filter Technology versus a Disc Filter

ZGF Spring Filter is also often compared with disc filter technology. But there is no comparison! – ZGF Spring Filter versus a disc filter.

If you want to learn more about the relationship between Spring Filter element flowrate and pressure drop, then click here to view the EZ Clean Phoenix flow / pressure curves.

If you know your flowrate and the level of filtration that you need, then you can click here to view the EZ Clean System Sizing table. This simplified sizing table allows you to pick the system that will meet your requirements.

The sizing table and flow / pressure curves are just two more ZGF tools designed to make your life easier. After referring to these tools, you probably have enough information to request a quote.

|

ZGF Spring Filter technology versus a disc filter |

||

|

ZGF Spring Filter |

Disc Filter |

Advantage |

|

316 Stainless Steel

|

Plastic

|

ZGF Spring Filter |

|

Continuous Coil wound with a variable pitch

|

Individual discs

|

ZGF Spring Filter |

|

Nidge

|

Valley

|

ZGF Spring Filter |

|

Maintenance Free

|

Frequent Maintenance

|

ZGF Spring Filter |

ZGF's Filtration Technology Advantages

Zero Gravity Filter’s EZ Clean Filtration Systems provide the best available technology for removing suspended solids and particulate matter from water and water-based process fluids. The EZ Clean Filtration Technology also maintains the lowest 10-year lifecycle cost and is extremely environmentally friendly; Zero Gravity Filter’s environmentally responsible design is the “green standard” and is highly respected throughout the industry.

Click on the link Success Stories to learn more about how our customers were able to realize value via implementation of ZGF EZ Clean filtration technology. We’ve probably helped somebody that has the same challenges as you!

| FEATURE | BENEFIT |

| Full 1-year warranty on filter assembly and 5-year warranty on filter elements | Reduces operating and maintenance costs. |

| Precision engineered absolute gap | Ensures consistent and efficient particle capture and removal from the process (captures and removes >99% of spherical particles equal to or larger than the precision machined filter element gap). |

| Fully automatic, self-cleaning operation | Requires no manual intervention freeing up labor for other value-added plant services. |

| Full 1-year warranty on Maggie assembly | Reduces operating and maintenance costs |

| Fully automatic, self-cleaning operation | Requires no regular manual intervention freeing up labor for other value-added plant services and reducing maintenance and operating costs |

| Uninterrupted flow even during backwash | 24-hour / 7-day operation, eliminates downtime and allows for optimized operational productivity. |

| In-line design | Eliminates need for additional pumps, motors and controls reducing maintenance and operating costs |

| Compact design | Saves valuable floor space |

| Low energy requirement | Reduces load on plant utilities and lowers operating costs. It uses less energy than a light bulb |

| Efficient and environmentally responsible design |

It uses <0.75 % of total feed volume for backwash. Creates no additional waste (i.e. no disposable media, no packaging for new media, etc.). It uses less energy than a light bulb. |

| Secondary batch processing system (Green Screen) | Allows for recovery of valuable process fluids and reduces waste |

| Permanent media, stainless steel body and cores | Does not require replacement, thereby reduces labor and disposal costs, and increases productivity |

| Minimal moving parts through simplicity of design | Increases reliability, thereby reducing maintenance and operating costs |

| The Spring Filter is a coil wound with a variable pitch | Allows the filter element to open evenly from top to bottom and “shimmer” during backwash ensuring that all contaminants are completely cleaned off the filter element with each backwash |

| Permanent media filter elements (316 stainless steel, high nickel alloy/Super Duplex) | ENVIRONMENTLY RESPONSIBLE. No disposable media lowers carbon footprint |

Automatic, Self-Cleaning, Liquid Filtration Systems

EZ Clean Filtration Systems provide a wide range of advantages for numerous applications throughout several industries.

Whether you are:

- Paint Center Manager sick and tired of dealing with bag filters in your paint pre-treatment system

- Manufacturing Engineer with machining and quality issues

- Galvanizing Line Supervisor struggling with fouled heat exchangers in the post anneal quench or elsewhere throughout the process

- Cold Mill Maintenance Planner dealing with issues due to dirty mill coolant

- Utilities Manager that must improve cleanliness of the cooling water to prevent fouling of compressor intercoolers and other heat exchangers.

- Water Treatment Chemical Supplier trying to improve the performance of your chemistry and reduce the total operating and life cycle costs of your customers cooling towers, chillers and heat exchangers.

- Water Treatment Manager trying to reduce the operating costs and improve the reliability of critical UF, MF or R/O membrane systems.

- Owner / Operator of a brine injection well trying to reduce operating costs and maximize the life of your well.

- Quality Engineer that must improve process reliability and component cleanliness in several parts washers

Contact Zero Gravity Filters for EZ Clean Filtration Systems Today

ZGF EZ Clean filtration technology is the ideal solution in several industries for many applications. Simplicity, consistency, reliability and the lowest life-cycle cost make EZ Clean filtration technology the only choice when you need to remove suspended solids, silt, grit, fines and other particulate matter from your process.

As your preferred partner, ZGF understands that filtration should not be a burden, rather a tool that improves quality and reduces cost. Let us help you meet your objectives and make your job easier! Please contact us for a free consultation or request a quote for an in-depth price analysis today.

Click on the links to watch the Phoenix video, Spring Filter video, the Phoenix animation and Spring Filter animation or download the Product Data Sheets to learn more about this innovative technology and these unique products.