Filtration to Protect Spray Nozzles and Maintain Process Reliability

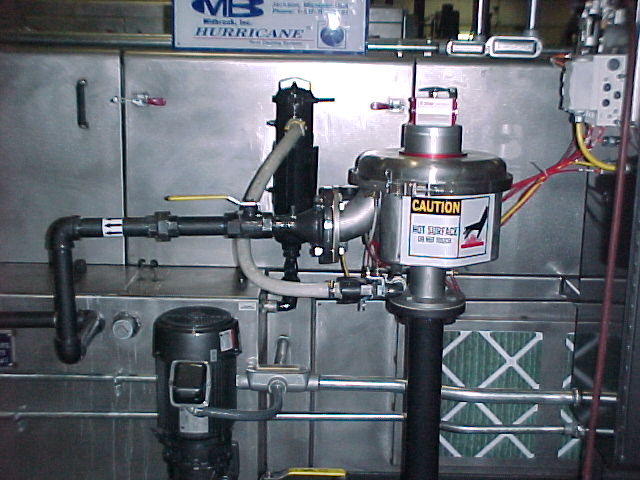

Spray Nozzles are used throughout industry for cleaning and rinsing, pollution control, and cooling. Clogged nozzles will negatively impact the effectiveness of the nozzles and thus the process. Filtration is highly recommended for spray nozzle protection. The best in class choice is the ZGF Spring Filter technology.

Spray Nozzles are found in virtually every industry.

|

|

Nozzles are designed to perform a specific function. Nozzle performance is dependent upon maintaining the design criteria for flow, pressure, coverage pattern and atomization. Effective and efficient filtration will help keep the nozzles clear of debris enabling the nozzles to consistently perform as designed.

Oversized particles as well high quantities of very small particles will plug nozzle orifices. Once plugged, the spray becomes uneven and inconsistent, and the process becomes compromised. Partially and completely plugged nozzles can

- negatively impact the process (process reliability),

- reduce productivity

- create unsafe work conditions

- increase maintenance costs, and

- lead to environmental and / or OSHA non-compliance

ZGF technology removes contaminants effectively and efficiently

Ultimately, inadequate filtration leads to partially or completely plugged nozzles, resulting in higher operating costs and lower profits! It can also lead to health & safety and environmental compliance issues.

Effective removal of the smaller and lighter suspended solids is extremely critical. ZGF Spring Filter technology provides a positive barrier that will capture and remove particles large and small, and light and heavy. You also want to minimize maintenance and labor which would make bag and cartridge filtration a poor choice. The Zero Gravity Filters permanent media Spring Filter is a coil wound with a variable pitch that allows the filter element to open evenly from top to bottom ensuring that all contaminants are completely cleaned off the filter element with every backwash. The ZGF Spring Filter is manufactured with precision raised nidges. These nidges create an absolute gap that allow the Spring Filter to capture > 99% of spherical particles larger than the micron rating of the filter.

ZGF Spring Filter technology effectively and efficiently captures and removes the contaminants prior to the spray nozzles.

ZGF Spring Filter technology is:

- fully automatic – the self-cleaning process is initiated based on pressure differential, and accomplished in seconds without interrupting flow to the process

- consistent & reliable

- non-disposable

- energy efficient – operates on line pressure, only utilizes a minimal amount of electricity and air during backwash cycle

- environmentally responsible - uses <0.75 % of total water volume for backwash

- able to remove particles down to 20 micron

ZGF technology provides value

Historically, people have used bag and cartridge filtration for these applications. The cost of using disposable bag and cartridge filters can add up quickly! Costs include:

- Purchasing bags and cartridges

- Disposing of bags and cartridges

- Changing bags and cartridges

- Shipping, handling and warehousing

- Issuing purchase orders and processing invoices

If true life-cycle costs are considered, typically the payback on ZGF Spring Filter technology can be realized in less than 1 year. This is based on ZGF Spring Filter technology:

- having no moving parts,

- operating costs of less than $100 per year, and

- a 5-year guarantee on the Spring Filter element.

Click on ZGF Phoenix vs Bag Filter to see a how a ZGF customer was able realize a simple payback in 8 months.

ZGF technology can provide significant value in several operations and applications. Click on Success Stories to jump to the Success Stories / Case Studies page to learn how ZGF technology

View the Spring Filter video and see how all the contaminants are removed during backwash when the filter element opens and shimmers.

Simplicity, consistency, reliability and the lowest cost of ownership make ZGF Spring Filter technology the best solution and value to protect your spray nozzles!

ZGF is your preferred partner.

Filtration should not be a burden.

Filtration should be a tool that improves quality and reduces cost.

Let us help you meet your objectives and make your job easier!

ZGF has the experience and dedication to customer satisfaction that you are looking for. Contact us or request a quote today.