Fluid Recovery System – Smart Drum & Green Screen

Machining coolants, metalworking fluids, quench fluids, wash solutions and many other fluids processed through the Magnetic Separator System (Maggie) are extremely valuable. These fluids are expensive to purchase and expensive to treat or dispose. By pairing ZGF’s Smart Drum or Green Screen fluid recovery systems with our Maggie or EZ Clean Filter Systems, you can virtually eliminate valuable fluid loss.

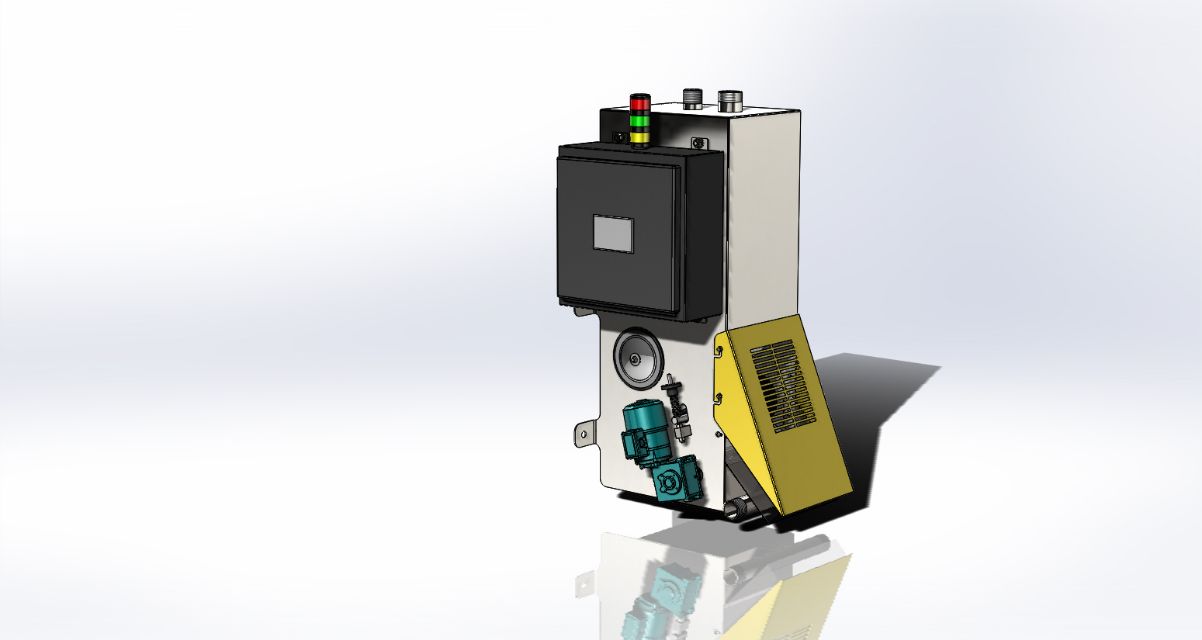

Smart Drum & Smart Drum Plus Fluid Recovery Systems

The Smart Drum and Smart Drum PLUS (SD) are fluid recovery devices. The SD is a fully automatic, batch process, magnetic separator that is used in conjunction with Maggie in-line separators. The purpose of the SD is to physically remove the magnetic fines from the Maggie purge fluid and return the clean fluid back to the process.

Smart Drum Fluid Recovery Device Operational Overview

- Purge fluid from Maggie flows to the SD at system pressure.

- The inlet diffuser and upper tank serve to reduce the pressure by acting as a surge tank.

- The fluid drains via gravity from the upper tank into the lower pan and across the magnetic drum before exiting the system. All fluid must pass across the magnetic field prior to discharging from the front of the unit. There is no by-pass flow.

- As the drum continues to rotate, the fines/chips are removed by the plastic scraper, and they drop onto the tray situated at the front of the drum.

- The fines/chips then fall off the tray and into a customer or ZGF supplied chip bin located below.

- The fluid from the SD is directed, via gravity, back to the process.

Click on the Maggie and Smart Drum animation to see a simplified process flow.

An optional wringer roller is also available. It is designed to reduce the liquid/moisture content of the solids/sludge that is removed by Maggie and is spring tension adjustable.

Smart Drum Fluid Recovery System Combined with Maggie Provides the Best Solution

Click on the desired Smart Drum model - Smart Drum or Smart Drum PLUS for a detailed product specification sheet. If you are looking for more information, go to Documents. You can download and access drawings, installation, operation & maintenance (IOM) manuals, as well as other technical and reference documents.

The below video shows how the SD works in tandem with Maggie to separate out the solids from the purge fluid and return the valuable fluid back to the process.

When the magnetic separator (Maggie) and the fluid recovery system (Smart Drum) are configured together as a system, ZGF can provide the best available & most environmentally responsible technology with the lowest 10-year lifecycle cost in the industry.

|

Smart Drum versus Smart Drum PLUS |

||||||

|

MG100 |

MG300 |

MG600 |

MG1200 |

MG2600 |

Multiple Maggie’s |

|

|

Smart Drum |

√ |

√ |

√ |

|||

|

Smart Drum PLUS |

√ |

√ |

√ |

√ |

||

Green Screen & Green Screen Plus Fluid Recovery Systems

The Green Screen and Green Screen Plus are backwash fluid recovery devices to be used with our EZ Clean filters. Like all ZGF technology, the Green Screen:

- Requires minimal maintenance or operator interface

- Provides consistent and reliable performance

- No disposable media

- Has a compact design

- Is SIMPLE, CLEVER & EFFECTIVE

Green Screen Fluid Recovery System Operational Advantages

While the Green Screen fluid recovery system is a manual device, the Green Screen Plus offers full automation. Both operate as gravity drain devices with an optional discharge pump available.

- Backwash fluid from a ZGF EZ Clean filter (i.e. Phoenix, EZ700S, EZ900, EZ700, EZ100) automatic, permanent media filtration system is directed into the Green Screen.

- The Green Screen utilizes a series of baffles to encourage settling of solids into the hopper.

- Smaller solids are captured by a permanent media filter.

- The permanent media filter is easily removed and cleaned, as required.

For more information about this simple and effective fluid recovery device, see our additional resources below:

Contact Zero Gravity Filters for Smart Drum & Green Screen Fluid Recovery Systems Today

As your preferred partner, ZGF understands that filtration should not be a burden, rather a tool that improves quality and reduces cost. Let us help you meet your objectives and make your job easier! Please contact us for a free consultation or request a quote for an in-depth price analysis today.

To learn more about this simple and effective fluid recovery devices, click here for a detailed Green Screen specification sheet, Green Screen Product Data Sheet or Green Screen product drawing.