Oil Removal Systems

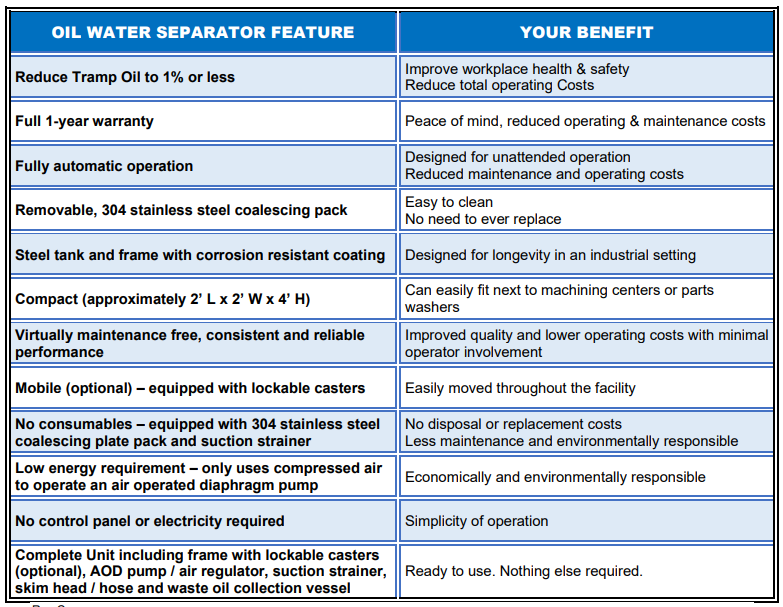

The ZGF coalescing oil water separator is designed to remove free and mechanically dispersed “tramp” oil from machining coolants, wash solutions, polymer quenchants and other water-based industrial process fluids.

PERFORMANCE & PHYSICAL CHARACTERISTICS

Nominal flowrate: 5 gpm (20 lpm)

Compressed Air Requirements: 50 – 80 psi (3 - 6 bar), clean & dry

Approximate Dimensions: 2’ L x 2’ W x 4’ H (570 mm x 590 mm x 1.070 mm)

Approximate Weight: 150 lbs. (65 kg)

Oil Water Separator Description and Operation:

Dirty, tramp oil laden fluid is skimmed off the surface through the 250-micron suction strainer to remove large particles, metal chips and fines and pumped via the onboard air operated diaphragm pump into the oil water separator.

The fluid flows across a stainless plate pack causing the oil droplets coalesce or gather to form larger oil droplets that float to the surface.

The oil layer on the surface increases until it eventually flows over the oil adjustable weir and into a waste oil collection vessel.

The clean fluid with typically less than 1% tramp oil flows under a weir out of the oil water separator and back to the process.

The ZGF coalescing oil water separator can provide significant value in several processes throughout the Automotive and Steel industries.

The ZGF coalescing oil water separator is designed to remove free and mechanically dispersed “tramp” oil from machining coolants, wash solutions, polymer quenchants and other water-based industrial process fluids.

Removal of tramp oil from these critical process fluids will improve workplace health & safety by reducing odors associated with microbial growth and airborne oil mist, as well as minimizing worker exposure to dirty process chemicals during sump cleanouts.

Effective removal of tramp oil will also reduce total operating costs and environmental impact by extending the life of these process fluids, reducing disposal costs, minimizing maintenance and labor, as well as improving the life of cutting tools in machining operations.

To learn more about ZGF Oil Water Separator, download the ZGF OWS Product Data Sheet.

ZGF HRM Cartridge

Specifications:

Filtration Media Material of Construction: Polyproylene with ZGF Proprietary Chemistry

222FEC End Cap Material and Dimenstions: 2.5" Polypropelene, Buna-N O-Ring

Maximum Operating Temperature: 160°F (72°C)

Maximum Opereating Differential Pressure: 35 psi @ 100°F (38°C)

Minimum Operating Pressure Required: 1 psi

Operating pH Range: 3-11

Operating Pressure Drop Across Media Upon Oil Removal: 1 psi

Typical Flow Capacities of HRM Based Systems: 1-10,000 gpm