Magnetic Separation and Filtration Remove Solid Contaminants from Machining, Grinding, and other Metalworking Fluids

Companies spend tens of millions of dollars to purchase and maintain machine tools. Every year they also spend millions of dollars on cutting tools, grinding wheels and metalworking fluids. A large machining operation could spend over a million dollars just on metalworking fluid and up to ten times that on cutting/grinding tools. Manufacturers of machine tools do a great job of making chips and fines. They often utilize settling zones and/or conveyors to remove the chips and fines from the metalworking fluid. Settling zones do not remove the chips from the process, they just defer the problem, and conveyors only address the chips, not the smaller fines.

Secondary filtration, such as bags, is often added to address the smaller fines. None of the commonly employed methods do a good job of removing the smaller fines from the process. If the contaminants (i.e. chips and fines) are not effectively removed from the process, the total operating cost of the process will be excessive. Poor contaminant control results in shorter tool life, shorter metalworking fluid life, excessive machine component wear, increased maintenance and excessive waste disposal.

You can have the best machine tools, use the best tools and the best metalworking fluids; BUT if you do not effectively and efficiently remove the contaminants from the process, you will not realize the full benefits of your investment.

ZGF technology provides value throughout the manufacturing cycle

Knowing and understanding component cost and value through the manufacturing cycle is critical. The investment and value of ancillary equipment such as filtration changes throughout the manufacturing cycle, and from process to process. Typically,

- The value of a component increases with each successive machining process / operation.

- The cost of perishable tooling also tends to increase with each successive operation.

- The quality / surface finish also becomes more important

As the value of the component increases and quality / surface finish requirements are more critical, investment in the best available filtration technologies becomes more prudent. If true life-cycle costs are considered for the filtration equipment and the machining operation, then economic justification for ZGF technologies is evident.

ZGF technology is a global standard and has been adopted as the best available technology for machining, honing, lapping, polishing, grinding, etc. within many well-known Fortune 500 manufacturing organizations. As they continue to implement our technology and realize the exceptional value, some organizations have shared their success stories.

ZGF technology can be installed in a variety of places in your process

ZGF Maggie and Spring Filter technology can be installed on:

- Stand-Alone Machining Centers

- Central Coolant Systems

- in-line to the machine / process

- as a side-stream filter (i.e. kidney filter)

Standalone Machining Centers

ZGF Maggie and Spring Filter technologies can be installed:

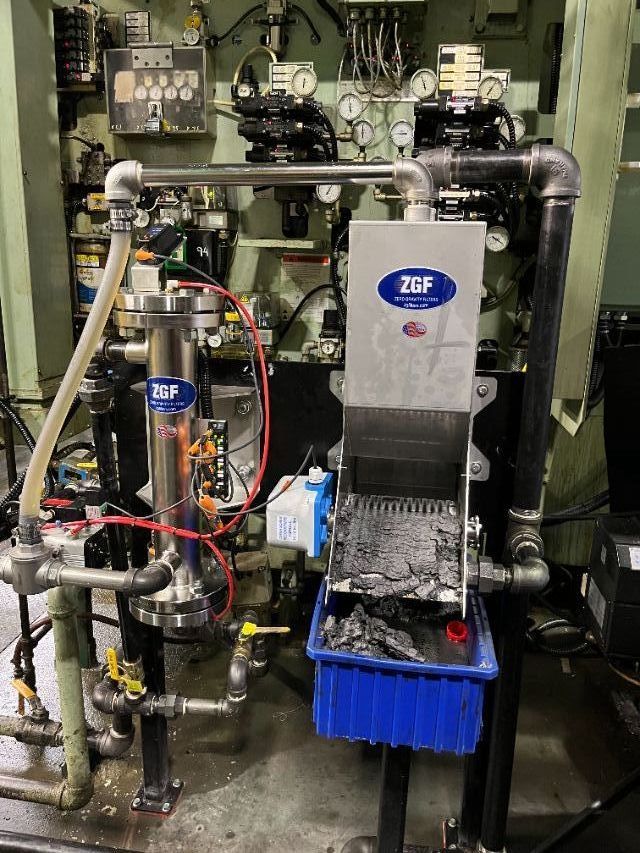

ZGF Maggie and Spring Filter technologies are often implemented on Stand-Alone Machining Centers with a single coolant tank.

ZGF technologies can be installed:

- in-line to the spindle / tool to prevent deposition and build-up of fines that could result tool breakage, increased scrap rate and reduced productivity,

- inline to the bed flush nozzles to prevent plugging of nozzles to help improve machine cleanliness, reduce machine maintenance and to help maintain overall coolant system health (i.e. maximize coolant life, minimize / prevent biological growth)

- as a side-stream filter providing continuous filtration of the coolant within the sump. The side-stream arrangement requires a dedicated pump. Dirty coolant is pumped from the tank through the ZGF Maggie and / or Spring Filter and back into the tank through eductors. The flow through the eductors continuously sweeps the bottom of tank directing any chips / fines toward the ZGF system.

Click to download the Process Diagram, Stand-Alone Machining Center, Single Tank.

ZGF Maggie and Spring Filter technologies are often implemented on Stand-Alone Machining Centers with a Clean tank / Dirty tank design.

ZGF technologies can be installed:

- in-line to the spindle / tool to prevent deposition and build-up of fines that could result in tool breakage, increased scrap rate, and reduced productivity,

- inline to the bed flush nozzles to prevent plugging of the nozzles and to help improve machine cleanliness, reduce machine maintenance, and to help maintain overall coolant system health (i.e. maximize coolant life, minimize / prevent biological growth)

- as a side-stream filter providing continuous filtration of the coolant within either the dirty tank or the clean tank. The side-stream arrangement requires a dedicated pump. Dirty coolant is pumped from the tank through the ZGF Maggie and / or Spring Filter and back into the tank through eductors. The flow through the eductors continuously sweeps the bottom of tank directing any chips / fines toward the ZGF system.

- on the transfer from the dirty tank to the clean tank / high pressure tank / super clean tank. You could also send a portion of clean fluid back through eductors in the dirty tank. The flow through the eductors continuously sweeps the bottom of tank directing any chips / fines toward the ZGF system.

Also, to optimize the machining operation it is best to design your filtration system so that the design flow capacity is 15% – 30% greater than the machine requires. This design consideration will allow for a 15% - 30% overflow from the clean tank back to the dirty tank. Continuous movement of the coolant and multi-pass filtration is highly recommended.

Click to download the Process Diagram, Stand-Alone Machining Center, Clean Tank / Dirty Tank.

Central Coolant Systems

In addition, ZGF Maggie and Spring Filter technologies can be implemented on large Central Coolant Systems too.

ZGF technologies can be installed:

- full-flow, downstream of the primary filter or chip conveyor and in-line to the spindles / tools of all the machines to prevent deposition and build-up of fines that could result in tool breakage, increased scrap rate, and reduced productivity,

- full-flow, downstream of the primary filter and inline to the bed flush nozzles of all the machines to prevent plugging of the nozzles and to help improve machine cleanliness, reduce machine maintenance and to help maintain overall coolant system health (i.e. maximize coolant life, minimize / prevent biological growth)

- as a side-stream filter (i.e. kidney filter) on the clean tank, the dirty tank, or both (i.e. clean and dirty tanks) providing continuous filtration of the coolant within either the dirty tank or the clean tank; or you could configure it to work on both the clean tank and dirty tank. The side-stream arrangement requires a dedicated pump. Coolant is pumped from the tank through the ZGF Maggie and / or Spring Filter and back into the same tank. It is recommended to return the filtered coolant back through eductors. The flow through the eductors continuously sweeps the bottom of tank directing any chips / fines toward the ZGF system.

- on the transfer from the dirty tank to the clean tank / high pressure tank / super clean tank. You could also send a portion of clean, filtered coolant back through eductors in the dirty tank. The flow through the eductors continuously sweeps the bottom of tank directing any chips / fines toward the ZGF system.

- downstream of the primary filter or chip conveyor to a specific machine tool or machine tools

ZGF Maggie and Spring Filter technologies are implemented many ways on central coolant systems. We have systems filtering 100% of the coolant to dozens of machine tools and systems filtering only a portion of the coolant to a couple of machine tools. The ZGF team can work with you to determine where in the central coolant system ZGF Maggie and Spring Filter technology can provide value.

To get a better understanding as to where ZGF Maggie and Spring Filter technology can provide value in your central coolant system, download the Process Diagram, Central Coolant System.

If your machining operations are primarily ferrous (i.e. cast iron, steel, powdered metal, CGI, etc.) and you want to learn more about ZGF Maggie technology, then download the Maggie Product Data Sheet or view the Maggie in action by watching the Maggie video.

If your machining operations are primarily non-ferrous (i.e. Aluminum, Brass, Titanium, etc.) and you want to learn more about ZGF EZ Clean technology, then download the Phoenix Product Data Sheet or the EZ Clean EZ700S Product Data Sheet or view the Spring Filter video and see how all the contaminants are removed during backwash when the filter element opens and shimmers.

ZGF Success Stories

Click on Success Stories to jump to the Success Stories / Case Studies page to learn how ZGF technology provides value. Click on the links below to learn how our customers were able to reduce operating costs, improve process reliability and quality, and reduce the environmental footprint of their metal removal operations by implementing ZGF

technology.

Contact the Magnetic Separation and Filtration Experts at ZGF Today

Keep your machine tools contaminant-free with ZGFs’ separation and filtration systems. We have provided innovative filtration solutions to customers for over 25 years. Let us help you keep your machine tools working optimally and without contaminant issues.

ZGF is your preferred partner.

Filtration should not be a burden.

Filtration should be a tool that improves quality and reduces cost.

Let us help you meet your objectives and make your job easier!

ZGF has the experience and dedication to customer satisfaction that you are looking for. Contact us or request a quote today.