Filtration & Magnetic Separation Products

Zero Gravity Filters (ZGF) is the leading manufacturer of advanced, automatic, liquid filtration and magnetic separation technology. ZGF provides efficient and effective liquid filtration and magnetic separation solutions that will minimize the lifecycle costs of individual processes and the total operation while also limiting the environmental impact of the process. Filtration should not be a burden. It should be a tool that improves quality and reduces cost. Selecting the ideal technology for each process is critical, and ZGF has expertise to help choose the best solution and the product technologies that will provide you the greatest value.

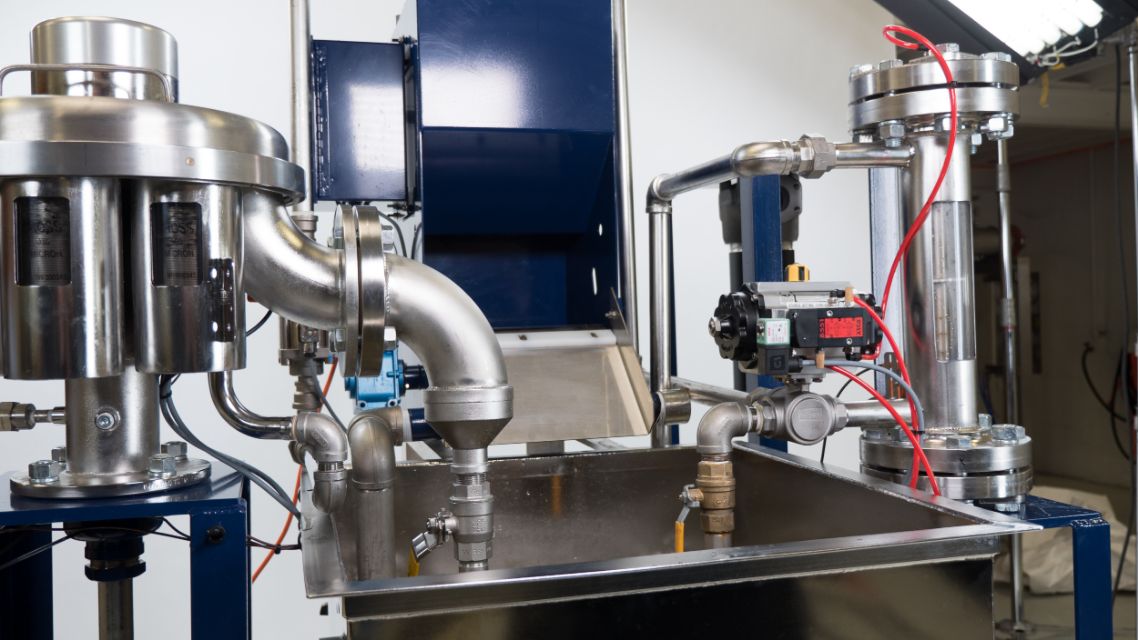

Maggie Magnetic Separator

The fully automatic, in-line, high intensity, patented Maggie magnetic separator is the best available technology for separating magnetic contaminants from process fluids. Maggie technology can remove particles as small as 1 micron without damaging critical process fluids such as machining coolants, cleaning / degreasing solutions or polymer quench fluids. The five Maggie models are designed to handle flow rates from 1 gpm to 250 gpm. Multiple Maggie's can be assembled in a manifold arrangement to meet any flow requirement. Maggie is the ideal solution in numerous industries for many applications.

Simplicity, consistency, reliability and the lowest life-cycle cost make Maggie the only choice when you need to remove magnetic contaminants from your process.

Click on the links to the life-cycle cost worksheets. Enter your actual costs to see how Maggie can provide value in your operation.

ZGF Maggie 10-year life-cycle cost

ZGF Maggie versus Bag Filters, 10-year life-cycle cost comparison

Check out the Maggie Magnetic Separator page to get additional information on this amazing technology! Click on the Maggie video to see it in action. The narrated video explains and allows you to see how Maggie works. Click on the Maggie and Smart Drum animation to see a simplified process flow.

EZ Clean Filtration Systems Featuring the ZGF Spring Filter Element

ZGF EZ Clean filtration systems (Phoenix and EZ Series) are the most advanced, best in class, automatic, non-disposable liquid filtration systems. All EZ Clean filtration systems utilize the ZGF Spring Filter element. The ZGF Spring Filter element is a 316 stainless steel coil wound with a variable pitch that allows the filter element to open evenly from top to bottom ensuring that all contaminants are completely removed from the filter element with each backwash. The Spring Filter is manufactured with precision raised “nidges”. These nidges create an absolute gap that allow the Spring Filter to capture > 99% of spherical particles larger than the micron rating of the filter element. A normal coil does not open evenly from top to bottom, causing ineffective cleaning. The full opening of the Spring Filter allows lodged or wedged particles to be easily removed as the gap is increased. While in backwash, the fluid flowing in the reverse direction causes the coil to open and shimmer which further enhances the cleaning capability of the backwash process. Click on the Spring Filter animation to see the basic principle of operation. To see the Spring Filter in action, click on the Spring Filter video. See the coil open and shimmer and the contaminants disappear!

The ability of the Spring Filter to open uniformly along its entire length during backwash provides three distinct benefits not achievable by automatic backflushing filters with fixed geometric screens (i.e. wedge wire, etc.). The benefits are as follows:

- Particles wedged or lodged are quickly released and washed away as the gap is increased / opened.

- Fluid flowing in the reverse direction causes the coils of the filter element to “shimmer” which further enhances the cleaning process.

- Fixed gapped filters do not allow enough fluid to flow in a reverse direction through a dirty filter, particularly at micron ratings less than 100. The ZGF Spring Filter, while open, allows increased fluid to flow in a reverse direction, providing the fluid necessary for effective cleaning. No high-pressure nozzles, scrapers, or motors required for cleaning.

The ZGF Spring Filter offers many advantages when compared to disc filters too!

Fluid Recovery Systems – Smart Drum & Green Screen

The Smart Drum and Smart Drum PLUS (SD) are fluid recovery devices. The SD is a fully automatic, batch process, magnetic separator that is used in conjunction with Maggie in-line separators. The purpose of the SD is to physically remove the magnetic fines from the Maggie purge fluid and return the fluid back to the process.

The Green Screen and Green Screen Plus are backwash fluid recovery devices to be used with our EZ Clean filters. While the Green Screen is a manual device, the Green Screen Plus offers full automation. Both operate as gravity drain devices with an optional discharge pump available.

Contact Zero Gravity Filters for Filtration & Magnetic Separation Products Today

As your preferred partner, ZGF understands that filtration should not be a burden, rather a tool that improves quality and reduces cost. Let us help you meet your objectives and make your job easier! Please contact us for a free consultation or request a quote for an in-depth price analysis today.